Media Report

- 2024-11-08

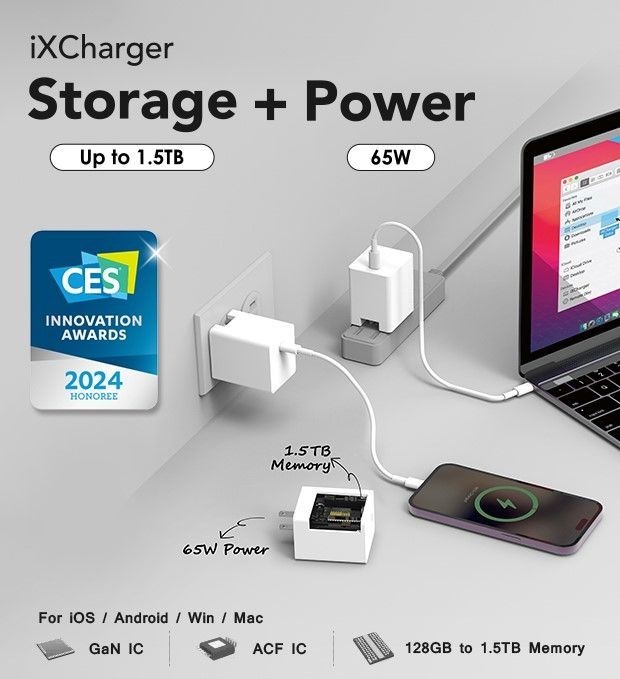

Phihong, in collaboration with Vinpower and Silanna Semiconductor, has developed the iXCharger 65W, which has been honored with an Innovation Award during the 2024 CES (Consumer Electronics Show). This first of its kind, two-in-one charger + storage device not only boasts an impressive storage capacity of up to 1.5TB, but also combines an efficient 65W … Phihong and Vinpower Collaborate to Create the ‘iXCharger 65W’ GaN Charger + Storage, Honored with a 2024 CES Innovation Award! Read More »

- 2024-11-08

The low Earth orbit (LEO) satellite market is ushering in a new era, delivering low-latency and high-efficiency communication solutions. With the miniaturization of devices, installation and manufacturing costs have significantly reduced, making LEO satellites the preferred choice across diverse applications. High-performance, long-life, and environmentally robust power technologies are indispensable in this market. With years of … Phihong Technology Enters Global Low Earth Orbit (LEO) Satellite Market with High-Performance Power Solutions Read More »

- 2024-11-07

Phihong Technology proudly received the “Best Employer Brand Award” at the inaugural 104 Employer Brand Awards, joining 45 other distinguished companies in recognition of its exceptional ability to attract and retain talent. This year’s Employee Value Propositions (EVP) of award-winning companies often focus on “Co-creation, Diversity, and Sustainability”—values that Phihong shares wholeheartedly. Phihong’s strength lies … Phihong Technology Wins Top Honor at the 104 Employer Brand Awards Read More »

- 2024-11-07

n response to climate change risks, Phihong has set a structured carbon reduction path aligned with climate adaptation strategies. In March 2024, Phihong received official target verification from the globally recognized Science Based Targets initiative (SBTi), underscoring its commitment to help limit global temperature rise to within 1.5°C. Phihong has proactively advanced its ESG … Phihong Passes SBTi Target Verification, Committing to 42% Carbon Reduction by 2030 Read More »

- 2024-11-07

In 2024, Phihong continued its comprehensive assessment of greenhouse gas emissions for 2023 across five key sites: the Linkou Headquarters, CHINOVA in Tainan, Dongguan Plant, Taisong Plant (including ZCM), and Haiphong in Vietnam. In May 2024, Phihong officially obtained a verification statement from AFNOR Asia, a French Standards Association, marking a significant milestone in our … Phihong Achieves 2023 ISO 14064-1 Verification, Strengthening ESG Carbon Reduction Efforts Read More »

- 2024-11-07

In response to climate change challenges, Phihong has taken proactive steps by achieving LRQA’s ISO 14064-1 greenhouse gas verification in December 2023, setting a milestone in the company’s low-carbon transition journey. To establish specific and effective carbon reduction goals and strategies, Phihong conducted a comprehensive assessment of greenhouse gas emissions for 2022 across five … Phihong Achieves ISO 14064-1 Verification, Declaring Commitment to Net Zero and Sustainable Development Read More »