Electric Bicycle Charging Basic Structure and Principles

Traditional chargers mostly utilize analog circuit design concepts. Even for key features like Constant Current (CC) and Constant Voltage (CV) modes, analog circuitry is still widely used. This increases circuit complexity and component count, which can, to some extent, reduce product reliability. However, Phihong Technology’s new generation of electric bicycle chargers have fully adopted digital control, using software design principles and a single MCU to replace traditional analog circuit designs. This technology can also be applied to battery-related products like drones and robots.

The digital control design offers numerous advantages, including intelligent charging features and protection mechanisms, which enhance charging efficiency and improve battery performance and lifespan. Here’s a breakdown of these features:

Digital Temperature Control:

Phihong’s electric bicycle chargers incorporate a digital control software developed in-house, allowing for temperature monitoring of critical components. Through a unique software algorithm, the charger adjusts the charging current and overall output power to control casing temperature, keeping it within a safe range of ambient temperature fluctuations (e.g., ΔT of 35°C).

Constant Power (CP) Charging Mode:

While traditional CC and CV charging modes are adequate for general battery charging applications, fast charging has become increasingly important in today’s efficiency-driven era. To address this, Phihong developed the Constant Power (CP) charging mode, which saves about 9% charging time compared to conventional methods without causing overheating. This technology was successfully patented in October 2019.

Battery Management System (BMS) Design Concept:

An effective BMS includes features such as State of Charge (SoC) detection, State of Health (SoH) management, balanced charging, and issue monitoring to avoid poor battery charging/discharging practices (particularly overcharging and deep discharging), thus preventing damage to both the battery and the charger, while minimizing system application loss.

Note: Balanced charging control is mostly used in batteries over 20 Ah (e.g., power batteries). This requires hardware and software integration to achieve optimal balancing control, ensuring each cell in the battery pack maintains similar charge levels.

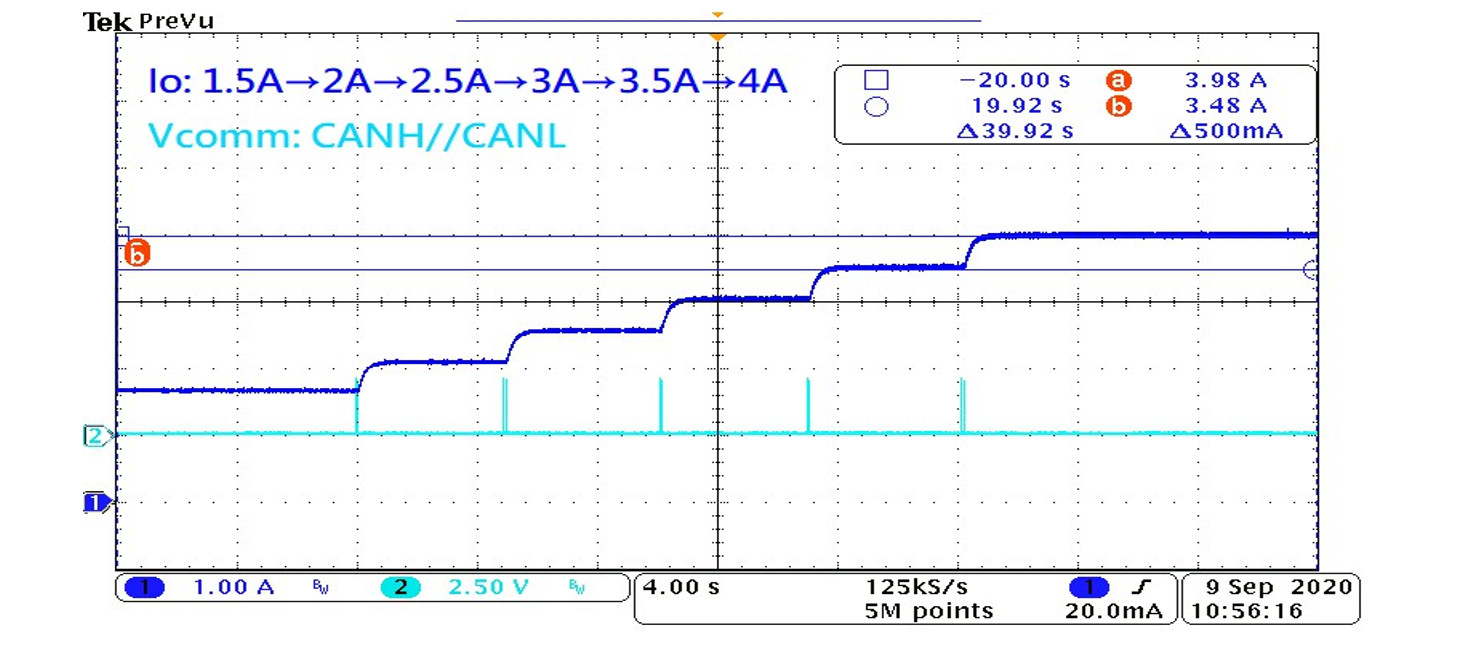

Software Communication Interface Applications:

Higher-end batteries often have integrated communication platforms (e.g., CANBus/I2C/SMBus, etc.), through which chargers communicate with the battery. Phihong’s electric bicycle chargers utilize these communication platforms to access relevant battery data (e.g., internal battery temperature) and adjust the charger’s output current, enhancing battery performance and lifespan.

How to Use an Electric Bicycle Charger

Phihong electric bicycle chargers are designed for simplicity—just select the compatible plug and socket, and charging will begin seamlessly. Higher-end chargers also come with software communication networks, enabling battery charging through mutual authentication once connected to an appropriate communication interface platform (e.g., CANBus/I2C/SMBus).

Before charging, please verify that the charger specifications match your battery’s, especially its rated voltage, to avoid overcharging or incomplete charging.

Phihong’s Electric Bicycle Charging Technology in Various Applications

Application Scenario 1: Electric-Powered Vehicles

This includes applications for electric cars, electric motorcycles, forklifts, electric boats, and drones. In essence, any vehicle using a power battery requires such charging products.

Application Scenario 2: Green Energy & Energy Storage Equipment Charging

As green energy becomes a global trend, energy generated from sources like solar, wind, or hydrogen fuel cells must be stored in batteries, with a charging system needed to convert and supply this energy to electric vehicles.

Using digital control technology, Phihong’s chargers can be used with various battery products, primarily lithium-ion and lead-acid batteries. Despite differing charge curves, Phihong strives to meet customer needs through customization.

Our mission and responsibility are to design products that provide “safety protection, fast charging, and intelligent monitoring,” delivering comprehensive and professional battery charging solutions.